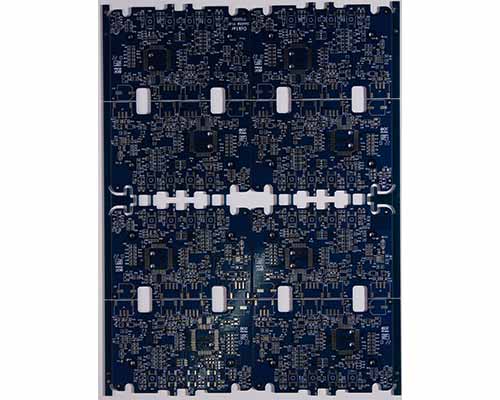

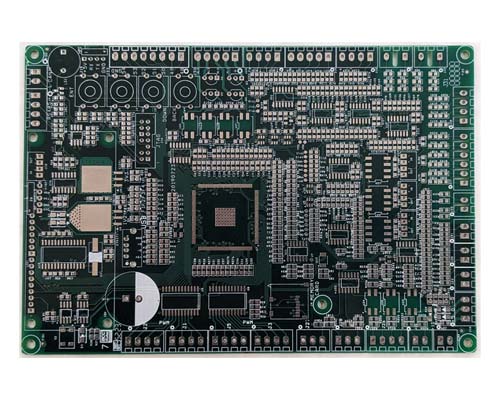

At the heart of every electronic product is a Printed Circuit Board, or a PCB, and the performance and life of each product depends hugely on the quality of its PCB. Which is why, we at BCC Fuba, have an uncompromising commitment towards quality to ensure that each PCB leaving our factory gates is in conformity with the internationally accepted standards.

Read More